Field Work

- Olivia Liu

- Jun 6, 2022

- 3 min read

An overview of the travels and events attended for this project.

Automate 2022 – June 5th, 2022

Automate 2022 is the largest trade show for automated technologies in North America.

I walked around the show floor to look at the machines and tools on display. If the technology displayed in a particular booth appeared unique and innovative, I stopped to introduce myself and my project topic to the representative at that booth. I asked them for their outlook on the effect of automated technologies on the manufacturing workforce and their comment on the importance of youth engagement in the manufacturing sector.

Booths

Below are the companies whose booths I visited. For international corporations, the listed locations belong to headquarters and facilities in North America.

Panel Discussion: The Workforce Crisis – Strategies for Cultivating Talent

Below are the panel members.

Main Takeways

In the interest of the future workforce, both educators and employers need to address the general lack of knowledge about the manufacturing sector among today’s youth.

Many youths, often those in financially privileged communities, believe that four-year college degrees are the “gold standard” credentials for acquiring stable and high-paying jobs. Due to the widespread conception that occupations in the manufacturing sector fall in the trade school pathway rather than the four-year degree pathway, these youths never even consider the field as a career choice.

With the development of automation, workers on factory floors will increasingly fulfill the roles of technicians rather than laborers. Assembly lines will require less manual human labor and, simultaneously, high-tech automated equipment will require more human maintenance.

Martinsville, Virginia – September 10th, 2022

Martinsville is a city in southwest Virginia with a population of just over 12,500. Surrounded by rolling hills, the city was historically known for its furniture manufacturing industry as the home of the major corporations Bassett Furniture and Hooker Furnishings. Today, Martinsville boasts a 1,000-acre industrial park that houses the manufacturing facilities of corporations in the food production, high-performance films, and textiles sectors. As of 2022, nearly 20% of Martinsville’s workforce is employed in the manufacturing sector.

I drove around the city of Martinsville, took pictures of various facilities, and observed the community’s layout.

Key Observations

Although a community of substantial size and resources, Martinsville is geographically isolated from other major communities. The roadways into the city run for 15-mile segments without passing any roadside facilities.

Martinsville’s manufacturing plants appeared to be the newest-looking and most well-maintained buildings in the community.

Martinsville is home to several types of educational institutions, from college institutes to vocational schools.

IMTS 2022 (International Manufacturing Trade Show) – September 12th, 2022

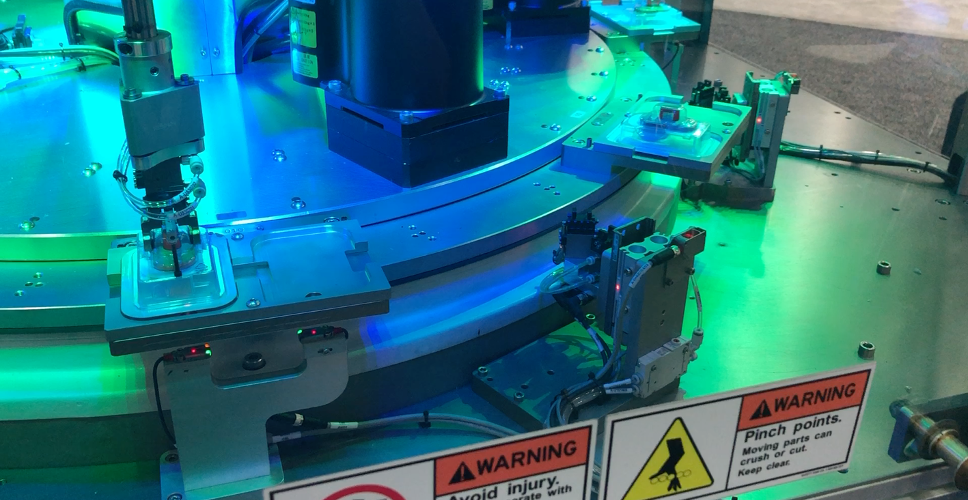

IMTS is the largest and oldest trade show for manufacturing in the Western Hemisphere. The technologies exhibited at the convention ranged from robotic arms to waterjets to CAD software. IMTS organized a show floor, branded as SmartForce, for youth attendees, in which youth were able to participate in interactive games, ask exhibitors questions about technologies on display, and even take in-person courses on manufacturing equipment. Corporations also used their SmartForce booths to present their workforce development efforts through brochures, posters, and slideshows.

Before attending the show, I created a list of SmartForce exhibitors to visit. Many of the booth representatives assumed I was simply a student who was part of a school field trip, so they immediately began introducing me to all the technologies in their exhibits. I inquired the representatives about the curriculums, manufacturing training initiatives, and youth outreach their companies had created and performed.

Booths

Main Discussion Points

Several corporations create extensive manufacturing curriculums for teachers in K-12 schools to adapt to their classrooms.

Many corporations construct machine equipment to be shipped to K-12 schools and vocational training institutions for use in hands-on learning and demonstration.

Comments